28.03.2025

Brake housings for autonomous driving

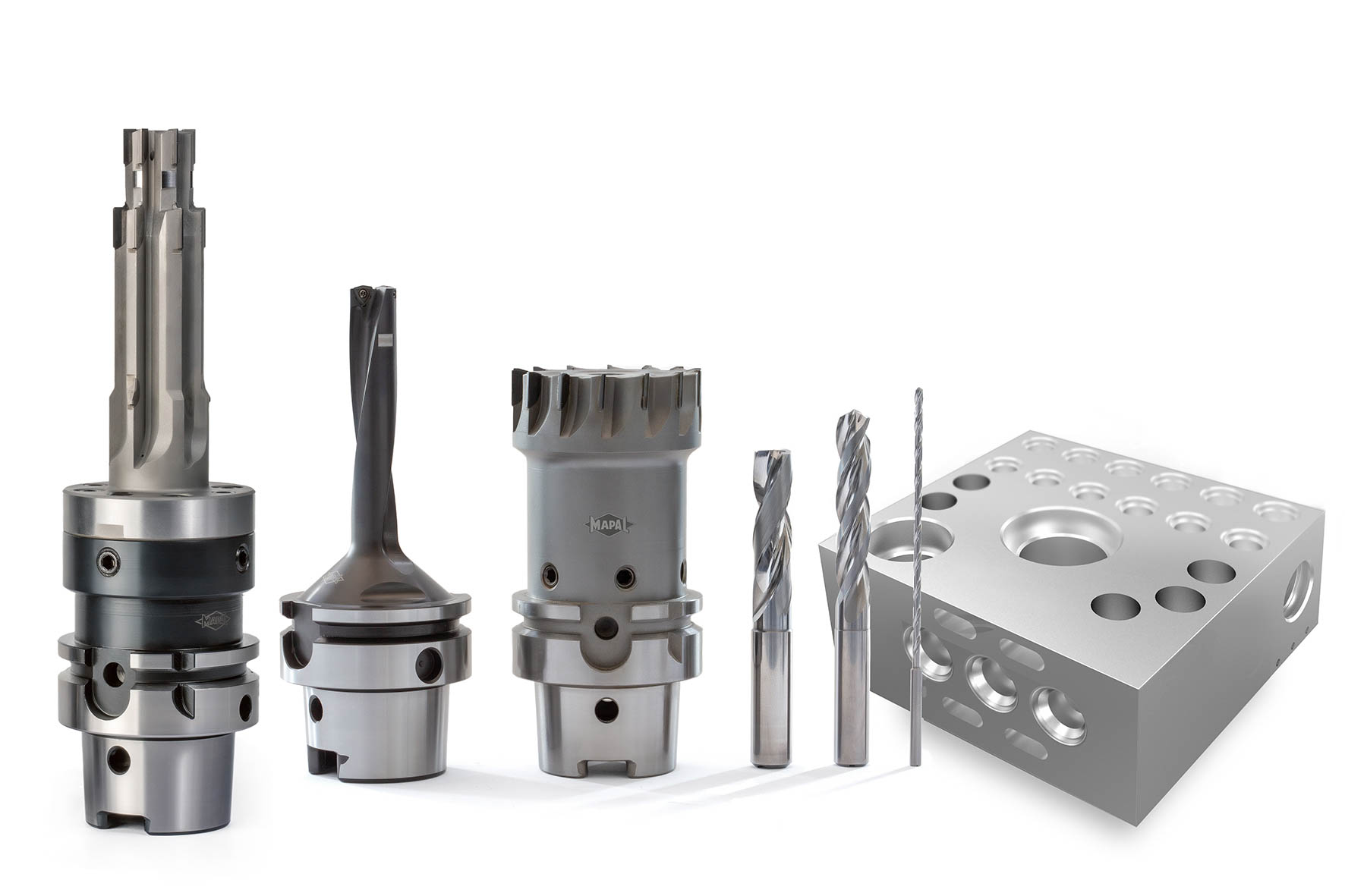

MAPAL's solution is a technically sophisticated combination

Combined brake housing unites main brake cylinder, brake booster and ABS/ESP in a single part. This component smooths the way for self-driving cars and saves weight. When it comes to machining complex aluminium workpieces, MAPAL’s solution expertise is very much in demand.

While self-driving cars are already permitted in various countries, the legal framework for them is still not in place in Europe, where only partial driving automation is permitted. The combined break housing – which unites the main brake cylinder, the brake booster and ABS/ESP in a single part – supports all levels of automated driving. Brake-by-wire is closely related to this, whereby the brake signal is no longer sent hydraulically but rather electrically.

A requirement for autonomous driving

Defined chip breaking for short aluminium chips

High demands on surface finishes

Productive drilling solutions save costs

Various deep bores are also drilled in the aluminium block, which overlap inside the component. Twisted tools with machining depths of up to 30xD ensure chips are removed reliably, so the liquids can later flow unhindered. The deep drilling alone takes up about 20% of the cycle time of approximately 15 minutes. Economical bore machining solutions thus have a considerable effect on overall cost efficiency.

Up to 5 million of the combined brake housing units are produced each year. They are predominantly produced in multi-spindle machines in two clamping setups. A four-spindle machine is preferred due to its high productivity. As a technology partner, MAPAL works with its customers to develop application-specific machining processes and tool packages for these aluminium parts.

Contact

Mathias Ostertag Public Relations mathias.ostertag@mapal.com Phone: +49 7361 585 3566